Putting up the Gypsum Board really starts defining the space!

This tool is called a banjo. The drywall tape is thread through as shown

and then the banjo is filled with drywall mud. The tape is used to seal

the joints of the drywall.

This tool was made out of scrap wood I had. I used it to hold up the

ceiling gypsum board. since my ceiling was going up on the floor joists

that were spaced 16" on center, I only used 1/2" gypsum board. If

the structural spacing was 24" (as typically found on roof trusses), then I

would have used 5/8" thick board. The extra thickness is necessary to span

the longer distance without sagging.

The greatest difficulty I had with the gypsum board is cutting the holes

for the electrical. It never seemed to line up right. Many times I just

had to add a small piece and secure it. It will get to be mudded over when

finishing and hopefully will not be too noticeable.

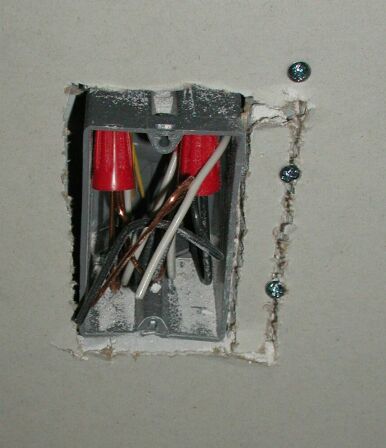

A view looking down on an electrical box in the Bathroom. A small

strip of wood was used as blocking to secure the gypsum board.

A view from the back.

In high moisture areas a special type of gypsum board is used. It is

resistant to moisture. The board is commonly called green board - can you guess

why? This makes it really easy for the building inspector to see that the right

board was used. Although technically the green board only needs to be used

in the shower/tub areas I used it throughout the whole bath as extra

precaution. Green board is used if prefab tub/shower units are used. If

the walls are going to be tiled a different board called cement board would be

used in the tile areas. Cement board is basically a thin sheet of concrete

with fibers.

Text coming soon

A view of the shower area. The window ledge only has a temporary

piece so that stuff doesn't fall down into the wall cavity. It will have a

wood sill when it is completed.

This door right now enters a storage area but in the future a hall could

be put in so this bathroom could have access from both the Guest Bedroom and the

hall.

A view of the door from the Guest Bedroom into the Bath. The gypsum

board is finished here.

A view of the Office window. At all corners metal corner beads are

installed to strengthen the edge. Then mud will be applied to cover it up.

Another view of the Office. Gypsum Board is installed horizontally

because that makes it easier to tape. Notice the vertical seams are

staggered. Also notice the dust on the floor! This part of the job

(and the sanding afterwards) was the messiest!

<prev ~ Back to Top ~ Next>